Leadership requires creating conditions that enable employees to do the kinds of experimentation that entrepreneurship requires. loc. 471

I’ve come to believe that learning is the essential unit of progress for startups. The effort that is not absolutely necessary for learning what customers want can be eliminated. I call this validated learning because it is always demonstrated by positive improvements in the startup’s core metrics. loc. 646

There are any number of famous entrepreneurs who made millions because they seemed to be in the right place at the right time. However, for every successful entrepreneur who was in the right place in the right time, there are many more who were there, too, in that right place at the right time but still managed to fail. loc. 1071

What differentiates the success stories from the failures is that the successful entrepreneurs had the foresight, the ability, and the tools to discover which parts of their plans were working brilliantly and which were misguided, and adapt their strategies accordingly. loc. 1077

What struck me

Before reading this book I thought I had a pretty good idea of the core idea of the Lean Startup methodology. I was sure it was all about generating a Minimum Viable Product* (MVP), sending that product to market, gaining feedback as to its success, and making changes accordingly (a process referred to as the Build-Measure-Learn loop).

Turns out there were a heap more gold nuggets hidden in this book than I expected. I’d like to explore those nuggets by first asking you two questions.

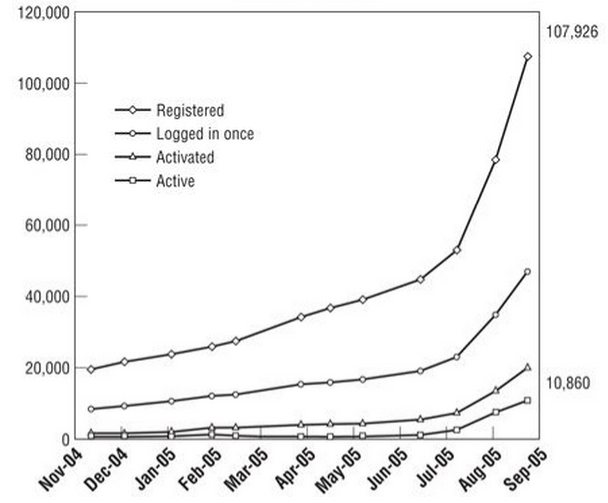

Question 1: Is company depicted in the graph below doing well? (from loc. 1654)

Question 2: Is it faster to fold, pack, seal and stamp one letter at a time (one piece flow), or is it faster to fold all of your sheets of paper in a batch, pack them in a batch, batch seal, and batch stamp them? (mass production).

*The MVP is that version of the product that enables a full turn of the Build-Measure-Learn loop with a minimum amount of effort and the least amount of development time. loc. 978

Answering Question 1: Innovation accounting-Actionable metrics vs. Vainty metrics

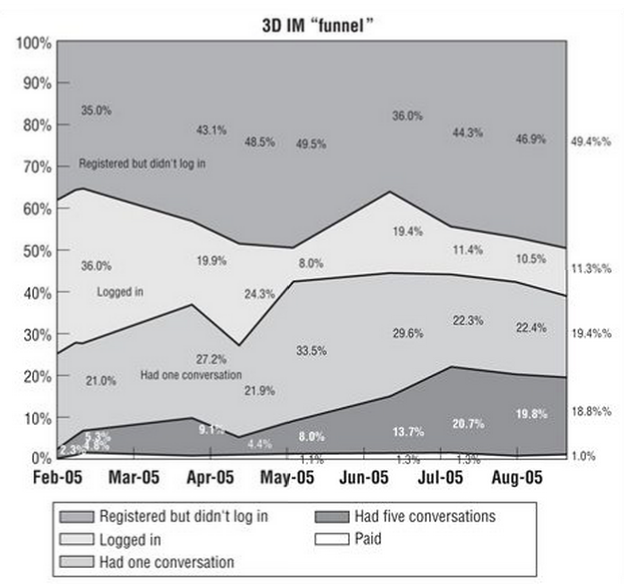

Chapter 7 of the book was, to me, the most valuable lesson of the book. It was about the difference between actionable and vanity metrics. What the ‘hockey stick’ image above shows is a company exhibiting exponential growth, but Reis suggests that this is a vanity metric. He tells us that the above graph actually doesn’t give us any useful information because it doesn’t tell us where the growth is coming from and, as such, it isn’t ‘actionable’. If a metric doesn’t give you information on how to take action (i.e., it isn’t ‘actionable’) then it’s useless. The actionable metric corresponding to the above graph would be the graph below. (from loc. 1577)

This above graph, known as a ‘cohort analysis’ shows the behaviour of customers over the same time period as the first graph, and it’s very telling. It shows that, regardless of what’s happening in our hockey stick graph, the percentage of customers who are paying for the given product isn’t changing, and is still excruciatingly low, hovering at around 1%. This is a clear indication that the product isn’t meeting the needs of the customers and the ‘tuning of the engine’, as Ries refers to it (the Build-Measure-Learn feedback loop) isn’t working effectively.

And so it is that Reis asks us “Are your metrics actionable, accessible, and auditable?”. Clearly the hockey stick graph doesn’t meet these criteria. The cohort analysis ticks these boxes.

Just briefly, on actionable, accessible and auditable:

- For a report to be considered actionable, it must demonstrate clear cause and effect. loc. 1841

- Accessible=employees can physically access and understand

- Auditable: We must ensure that the data is credible to employees. loc. 1886

Answering Question 2: Packing Envelopes-Mass production or One Piece Flow?

I was pretty surprised when I watched this video. It really goes against all we expect in terms of the batching that occurs in mass production, the likes of which we generally consider to be ‘efficient’. I guess it depends on what you’re doing, but reflecting upon my study of Mandarin Chinese, I know that if I had have applied this one piece workflow approach I would have done better. There were times when I found a great learning resource, spent heaps of time ‘organising’ it for learning (e.g., putting it into Anki cards), only to find a ‘better’ resource and move onto that one before actually studying the previous one… One piece in this case would have meant that lessons were learned better on the way, rather than focussing on ‘the best way to study’, and not actually doing the study (procrastination-by-organisation!)

Lean startup in a nutshell

Above is my key take home from The Lean Startup. But there’s a heap more in there that’s really worth looking at. Check out the notes in this blog body, and then the full book summary in the google doc insert. In a nutshell, the Lean Startup approach is all about the difference between driving a car and calibrating the launch of a spaceship. When driving a car you are constantly taking in new information and adjusting your journey (steering, accelerator, brake) based on continuous feedback, in a spaceship you need to set all your parameters prior to launch and just hit the go button. Reis argues that in the startup world of ‘great uncertainty’, we’d do best to think of our startups as cars (which raises questions about how the advent of self-driving vehicles can inform our startups…self-correcting businesses? Who knows, I’ll think about it!)

A bit more…

Book layout

The book is split into three sections. Vision sets out principles, defining entrepreneurs, etc. Steer is about the Lean Startup method and goes into the build-measure-feedback loop. Accelerate talks about the techniques needed to follow the Lean Startup methodology.

Two Important Assumptions

The two most important assumptions entrepreneurs make are what I call the value hypothesis and the growth hypothesis. loc. 800

- The value hypothesis tests whether a product or service really delivers value to customers once they are using it. loc. 801

- The growth hypothesis, which tests how new customers will discover a product or service, loc. 807

The Four Engines of Growth

- The Sticky Engine of Growth

- The Viral Engine of Growth

- The Paid engine of Growth

- Sticky: The rules that govern the sticky engine of growth are pretty simple: if the rate of new customer acquisition exceeds the churn rate (the fraction of customers in any period who fail to remain engaged with the company’s product.), the product will grow. loc. 2731

- Viral: products that exhibit viral growth depend on person-to-person transmission as a necessary consequence of normal product use.

- Paid engine of Growth: Each customer pays a certain amount of money for the product over his or her “lifetime” as a customer. Once variable costs are deducted, this usually is called the customer lifetime value (LTV). loc. 2806

Four questions for product development

- Do consumers recognize that they have the problem you are trying to solve? loc. 844

- If there was a solution, would they buy it? loc. 845

- Would they buy it from us? loc. 846

- Can we build a solution for that problem?” loc. 846

Pivot of Persevere?

The decision to pivot (i.e., change the direction of your company) is emotionally charged for any startup and has to be addressed in a structured way. One way to mitigate this challenge is to schedule the meeting in advance. I recommend that every startup have a regular “pivot or persevere” meeting. In my experience, less than a few weeks between meetings is too often and more than a few months is too infrequent. However, each startup needs to find its own pace. loc. 2145

The Five Whys

The system takes its name from the investigative method of asking the question “Why?” five times to understand what has happened (the root cause). loc. 2984

At the root of every seemingly technical problem is a human problem. Five Whys provides an opportunity to discover what that human problem might be. loc. 2988

Key Vocab

The importance of basing strategic decisions on firsthand understanding of customers is one of the core principles that underlies the Toyota Production System. At Toyota, this goes by the Japanese term genchi gembutsu, which is one of the most important phrases in the lean manufacturing vocabulary. In English, it is usually translated as a directive to “go and see for yourself” loc. 1097

Peter Thiel’s take on the Lean Startup

I also recently read Peter Thiel’s book on innovation entitled Zero to One (Wot-I-Got notes here). He’s more of a fan of the spaceship approach (intelligent design) than the car driving approach (Lean Startup). For interest, I just thought that I’d include here a couple of quotes pertaining to this from his book…

Darwin’s theory explains the origin of trilobites and dinosaurs, but can it be extended to domains that are far removed? Just as Newtonian physics can’t explain black holes or the Big Bang, it’s not clear that Darwinian biology should explain how to build a better society or how to create a new business out of nothing. loc. 812

leanness is a methodology, not a goal. Making small changes to things that already exist might lead you to a local maximum, but it won’t help you find the global maximum. loc. 820

Darwinism may be a fine theory in other contexts, but in startups, intelligent design works best. loc. 823

Full Book Notes